Reduce Down Time with Timken

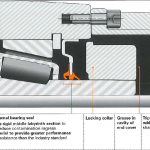

Posted on Sep 11, 2018Timken’s steel auxiliary covers offer an excellent sealing solution for the harshest environments. Timken offers both an open end and closed end design that bolts directly onto the casting, encapsulating the insert bearing and adding an extra layer of protection. These covers are made from steel and treated with a black oxide coating to withstand harsh environments. The covers are made for the Spherical Bearing housed units and have the option to be filled with grease once they are bolted onto the bearing. The grease provides an excellent extra barrier to stop contamination and prolong bearing life.

Due to the success of the Spherical Bearing covers, Timken has recently released a line of covers for their Type E housed bearings. Offering the same cost-effective design, these Type E covers come standard with a triple lip seal and a grease fitting, allowing you to fill the cavity inside the cover with grease. Similar to the Spherical Bearing covers, the grease and extra seal add a layer of formidable protection that has been proven to withstand some of most severe conditions.

If you are currently having contamination issues on any housed bearing units give Standard Bearings a call and find out how we can help increase the life of your bearings!