Detect Leaky Rotating Unions with Deublin’s SpindleShield® Technology!

Posted on Jun 28, 2021Standard Bearings offers a full range of Deublin’s patented SpindleShield® technology for use in the Machine Tool industry. This technology is designed to protect spindles by reliably warning users of internal leakage of coolant unions.

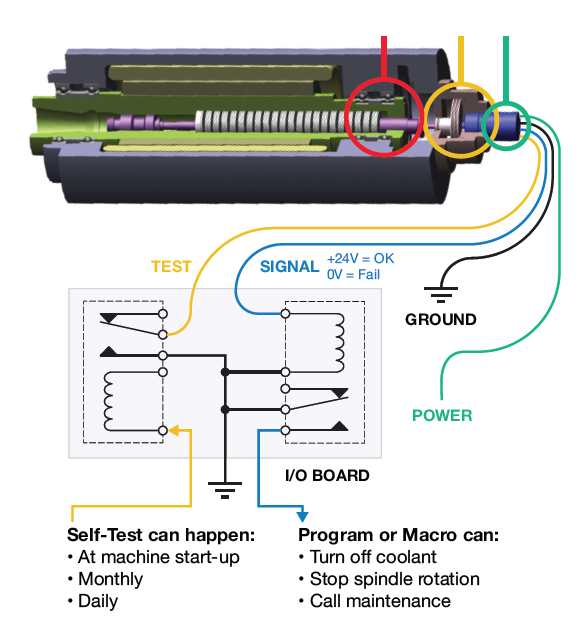

How does it work? The SpindleShield® system prevents spindle failures by sending a warning to the machine of leakage due to excessive seal wear. This signal can be sent to an unused relay on an existing I/O board, and unassigned M-code can check status of that relay.

Features of the SpindleShield® System:

- 2 years battery life outside monitoring unit

- Wireless communication

- ESD (Electrostatic Discharge) protection

- Visual and audible alert

- IPx7 rated Detection Unit

- Resistant to hydraulic oil and coolant

- Fail safe design, notifies user when wires get disconnected

- Optional cloud monitoring feature available

What Options are Available?

1. Closed Seal Technology: Deublin rotary unions with closed seal technology keep the sealing surfaces in constant contact. Closed seal unions generally are less affected by extremely contaminated coolant than other designs. Generally, closed seal unions should not be rotated for an extended time if coolant is not present.

2. Pop-Off® Technology: Pop-Off® seal technology closes the seals only when pressure is applied. When pressure is removed, the seal faces separate by a very small distance. This eliminates friction and seal wear during operation without coolant, and therefore allows unlimited “dry running” at high speeds.

3. AutoSense®: AutoSense® technology combines the best features of Pop-Off® and controlled leakage designs. Like Pop-Off® designs, AutoSense® seals close when coolant pressure is applied to contain the coolant fluid, and “pop” apart in the absence of coolant pressure to allow unlimited dry running. Like controlled leakage designs, AutoSense® seals handle pressurized dry air by creating a microscopic gap between the seal faces.

Call Standard Bearings today for all your machine tool monitoring needs!